VIDEO

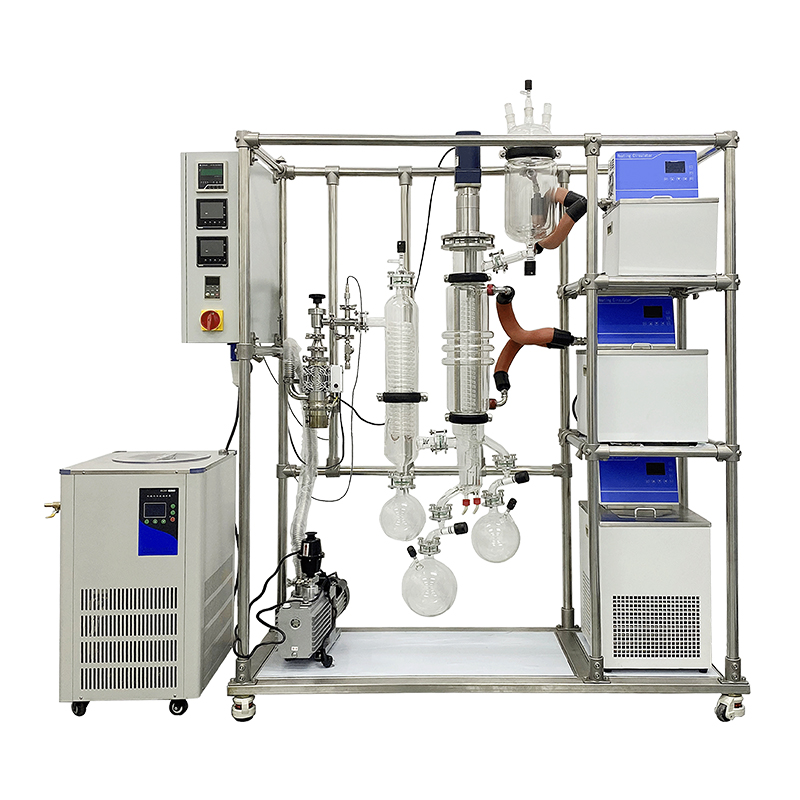

6 Advantages Of OQITOP Molecular Distillation System

- 1. High-quality control box, the control box controls the speed and temperature, easy to operate.

- 2. Ball-shaped ground connection to improve vacuum better.

- 3. Diffusion pump, increase the vacuum degree, and improve the purity of the material.

- 4. The scraper is perpendicular to the main evaporator, and its wear resistance is 6 times that of the PTFE scraper.

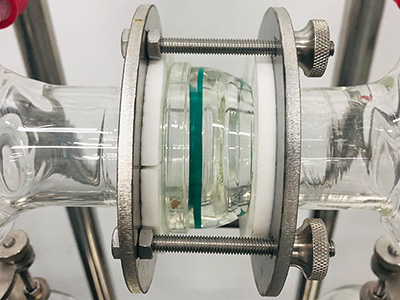

- 5. Magnetic sealing, no leakage, high vacuum, good stability.

- 6. High borosilicate glass collection bottle, corrosion resistant.

DESCRIPTION

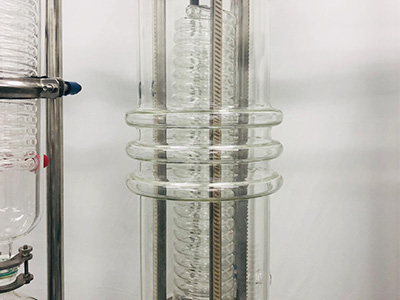

Molecular distillation is a special liquid-liquid separation equipment. Unlike traditional distillation, it relies on the boiling point difference separation principle, but on the difference of the average free path of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules will escape from the liquid level and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances move different distances after escaping from the liquid level. After passing through the built-in condensate pipe of the main evaporator, the light molecules reach the condensate pipe and are discharged, while the heavy molecules cannot reach the condensate pipe and are discharged along the mixed liquid, So as to achieve the purpose of material separation.

Working Principle

The materials are transported from the feed tank to the jacketed main evaporator. The main evaporator is continuously heated. The built-in scraper evenly scrapes the materials into a layer of flowing liquid film for instant evaporation. The light component materials begin to vaporize and adsorb on the built-in condensing coil, flow into the receiving bottle along the outer wall of the condensing pipe, and the heavy component materials flow into the receiving bottle along the inner wall of the main evaporator.

Application

Extraction of deep sea fish oil |

Extraction of CBD oil |

Pharmaceuticals |

Concentration of plant essential oil |

Separation of vitamin / nutritional essential oil |

Chemical Research |

FEATURES

1. All glass is made of borosilicate GG17

2. Use spherical grinding to keep a high vacuum

3. All interfaces use a spherical shape to ensure vacuum

4. From bio mass to CBD oil or crude to CBD oil we can provide turnkey

5. The controller box is imported and easy to operate, Digital display speed and temperature

6. The scraper is made of polyphenylene, and the wear resistance is six times that of ordinary PTFE.

7. High evaporation efficiency, process time short

8. The residence time is short, and the thermal sensitive material is not easy to deteriorate andcarbonize

9. The connection port adopts ball milling port design to ensure that molecular distillation isalways in high vacuum

10. Glass material,easy to observe process program

11. Can reach 0.1Pa with diffusion pump and high efficiency distillation

12. The main evaporator adopts jacket design, with high heating efficiency and strong thermalinsulation performance

13.Can continuous feeding and discharging

Precautions for use

1. Fill the cold trap with liquid nitrogen for freezing in advance

2. Equipment heating with oil,high temperature,do not touch with hand,avoid scalding

3. Work temperature from -80℃ to 250°℃ (300C need customized)

4. Check cooling water valve is open normal or not before use

SPECIFICATIONS

| Model | LGMD-60B | LGMD-80B | LGMD-100B | LGMD-150B | LGMD-200B | LGMD-230B |

| Main evaporator diameter(mm) | 60 | 80 | 100 | 150 | 200 | 230 |

| Effective evaporation area(㎡) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

| Feed rate(Kg/h) | 0.5-3.0 | 1.0-5.0 | 2.0-8.0 | 3.0-15.0 | 5.0-20.0 | 8.0-30.0 |

| Feed tank volume(L) | 1 | 1 | 2 | 2 | 5 | 5 |

| Speed(r/min) | 450 | 450 | 450 | 450 | 300 | 300 |

| Volume of light component collect flask | 1L | 1L | 2L | 3L | 5L | 5L |

| Volume of heavy component collect flask | 1L | 1L | 2L | 3L | 5L | 5L |

| Motor power(W) | 90 | 120 | 120 | 120 | 200 | 200 |

| Work temperature | -90℃~220℃ | |||||

| Voltage | 220V/50Hz can be customized | |||||

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of molecular distillation system machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

EXHIBITIONS & EVENTS

We have just participated in the Canton Fair. During the exhibition, our products attracted many customers with their innovative design and excellent performance, and were loved and recognized by many customers. The on-site exchanges were lively, and many customers expressed strong intentions to cooperate. We look forward to cooperating with you and providing you with high-quality products and services.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe OQITOP, we grow together!