In the realm of advanced materials science, precision-engineered components are the cornerstone of groundbreaking research. Our company is proud to announce a successful collaboration with IMDEA Materials Institute (Instituto Madrileño de Estudios Avanzados en Materiales), a globally renowned research hub in Madrid, Spain, by delivering custom-manufactured nickel foam tailored to their rigorous research requirements.

IMDEA Materials Institute stands at the forefront of innovation in materials engineering, focusing on critical areas such as energy storage, sustainable manufacturing, and advanced materials processing. To support their pioneering work, the institute required nickel foam with specific dimensional and structural properties— a challenge our team embraced with expertise and precision.

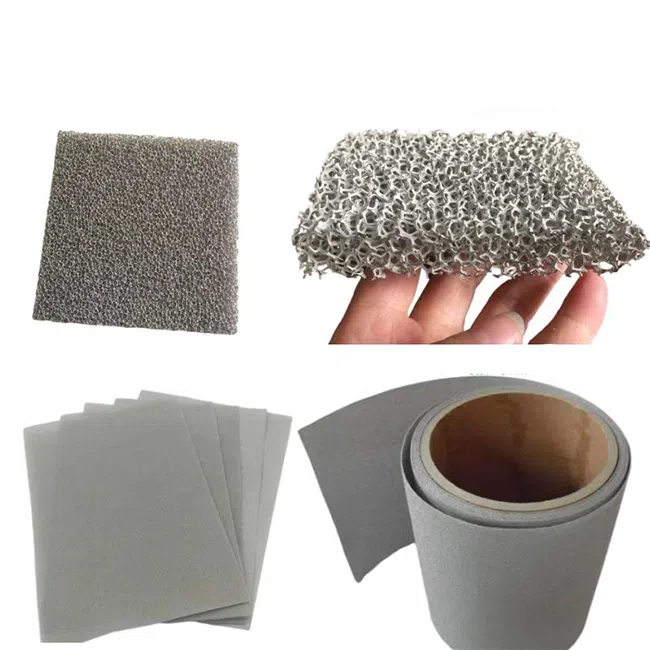

The custom nickel foam we developed meets IMDEA’s exact specifications: a precise dimension of 200mm×200mm×3mm, paired with a versatile pore size range of 10PPI to 200PPI. This broad PPI spectrum is a key advantage, as it allows the institute’s researchers to explore applications across multiple domains. Lower PPI (10-50PPI) variants offer excellent fluid permeability and structural stability, ideal for filtration and energy conversion systems, while higher PPI (100-200PPI) options provide an ultra-large specific surface area, perfect for catalyst carriers and high-performance battery electrodes—core areas of IMDEA’s research portfolio.

Crafting this specialized nickel foam demanded uncompromising attention to quality and consistency. Our manufacturing process ensures a high nickel purity of over 99%, delivering superior corrosion resistance and mechanical strength that withstands the institute’s rigorous experimental conditions. The 3mm thickness, combined with the 200mm×200mm planar dimension, balances structural integrity with flexibility, enabling seamless integration into various lab-scale setups, from electrochemical cells to material characterization systems.

Nickel foam’s unique three-dimensional porous structure has long been valued in advanced materials research, thanks to its ability to enhance mass transfer, electron conductivity, and reaction efficiency. For IMDEA Materials Institute— which leads research in energy generation/storage and sustainable materials—this custom solution opens new avenues for exploring next-generation batteries, hydrogen production technologies, and environmental remediation systems. Whether testing electrode performance for energy storage devices or optimizing catalyst support structures, the tailored PPI range and precise dimensions of our nickel foam provide researchers with a reliable, consistent platform for their experiments.

This collaboration with IMDEA Materials Institute underscores our commitment to supporting scientific excellence through customized materials solutions. Our team worked closely with the institute’s researchers throughout the development process, from initial specification refinement to final product validation, ensuring the nickel foam aligns perfectly with their research objectives. By combining advanced manufacturing capabilities with deep material science expertise, we deliver components that empower researchers to push the boundaries of what’s possible in advanced materials.

As IMDEA Materials Institute continues to drive innovation in sustainable technology and advanced manufacturing, our custom nickel foam will play a vital role in accelerating their research outcomes. We are honored to be a trusted partner in their mission to develop materials that address global challenges in energy, environment, and industry—proving that precision-engineered materials are the foundation of tomorrow’s breakthroughs.