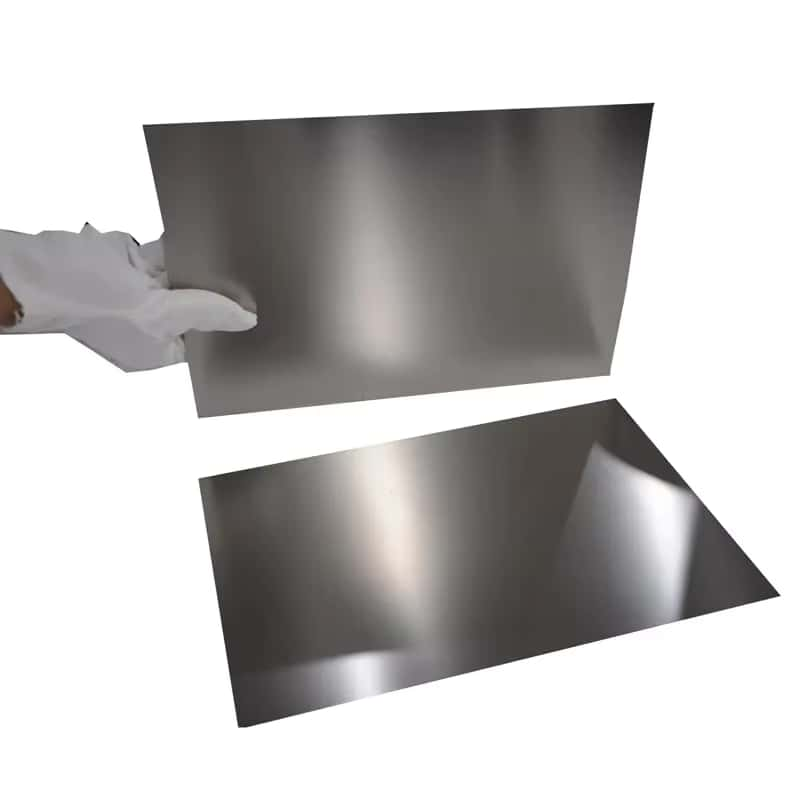

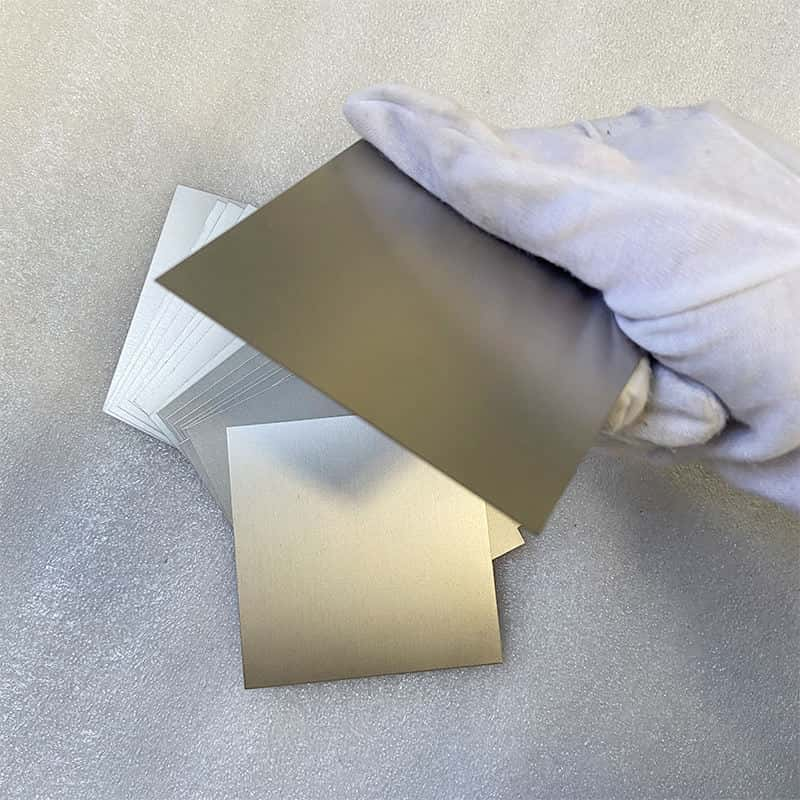

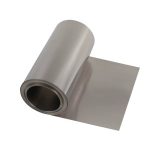

Customized 99.95% Purity Tungsten Foil 0.01-0.9mm Thin Surface Polished for LED Heat Sinks & X-Ray Equipment Components

Tungsten foil is produced by cold rolling the tungsten sheet to a lower thickness. The stamped and drawn foil is very suitable to use in the applications of high temperature vacuum furnace, coating, electronic and semiconductor components. Tungsten foil is used to make heat shielding, heating element and carrier of the vacuum furnace. It is because tungsten foils process a high heat resistance in the high temperature environment.

In addition, tungsten foil owns an extremely Low Vapor Pressure and a high melting point so that it is ideally served for coating application as the evaporation boat. Moreover, the ideal material for semiconductor needs to have a Low Coefficient of Thermal Expansion and Low Electrical Resistivity. Tungsten can meet these requirements. Therefore, it is a very suitable material for components of the semiconductor industry. Tungsten has been also approved to be a promising material to explore in further in medical and Sputtering applications.

TUNGSTEN PLATE INFORMATION

| Standard | 純度 | Density | Melting Point | Thickness Range | Size |

|---|---|---|---|---|---|

| ASTM B760, GB/T 3975 | ≥99.95% | 19.3 g/cm3 | 3410 ℃ | > 4.75 mm | Custom width and length |

TUNGSTEN PLATE CHEMICAL COMPOSITION

| W (≥%) | Chemical Content (≤ %) | |||||||

|---|---|---|---|---|---|---|---|---|

| 99.95 | K | Fe | Al | Mo | Si | As | Ca | Cr |

| 0.0015 | 0.003 | 0.003 | 0.003 | 0.0015 | 0.001 | 0.001 | 0.001 | |

| Mg | Mn | Na | Ni | Bi | Cd | Cu | Pb | |

| 0.001 | 0.001 | 0.001 | 0.001 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

| Sb | Co | Ti | Sn | |||||

| 0.0005 | 0.0005 | 0.0005 | 0.0005 | |||||

Product Advantages

1.Unmatched High-Temperature Performance:

Characteristics: Tungsten plates boast a melting point of up to 3422°C and can maintain stable operation at temperatures ranging from 1800°C to 2600°C. The high-temperature strength and sag resistance greatly exceed those of most metallic materials.

Advantages: Serving as thermal shields, heating plates, and furnace beds in high-temperature vacuum furnaces, tungsten plates can efficiently concentrate heat while bearing the weights of workpieces. This capability generates a pure, stable high-temperature environment ensuring extended service life and high reliability.

2.Exceptional Physical Shielding Properties:

Characteristics: Thanks to their high density, tungsten plates provide outstanding shielding effectiveness against X-rays and gamma rays.

Advantages: Ideal for manufacturing collimators for medical CT, radiation shield blocks, containers for nuclear fuel handling, and shielding components for industrial non-destructive testing equipment, tungsten plates deliver excellent protective performance even at thinner gauges.

3.Superior Structural Strength and Stability:

Characteristics: Tungsten plates exhibit excellent strength and hardness at both high temperatures and room temperatures, along with outstanding creep resistance.

Advantages: As components in electronic beam evaporation boats and carriers within semiconductor process chambers, tungsten plates maintain dimensional stability under harsh process conditions, minimizing deformation and ensuring process repeatability and product consistency.

4.Good Thermal and Electrical Conductivity:

Characteristics: Tungsten plates possess good thermal and electrical conductivity.

Advantages: They are suitable for use as heatsinks or heat spreaders in high-power semiconductor devices, enabling swift heat dissipation. Additionally, tungsten can be a substrate for resistance welding electrodes, enhancing the performance of welding applications.

5.High Purity and Flexible Customization:

Characteristics: Available tungsten plates are of high quality. They are provided in various thicknesses and widths, tailored to specific customer requirements.

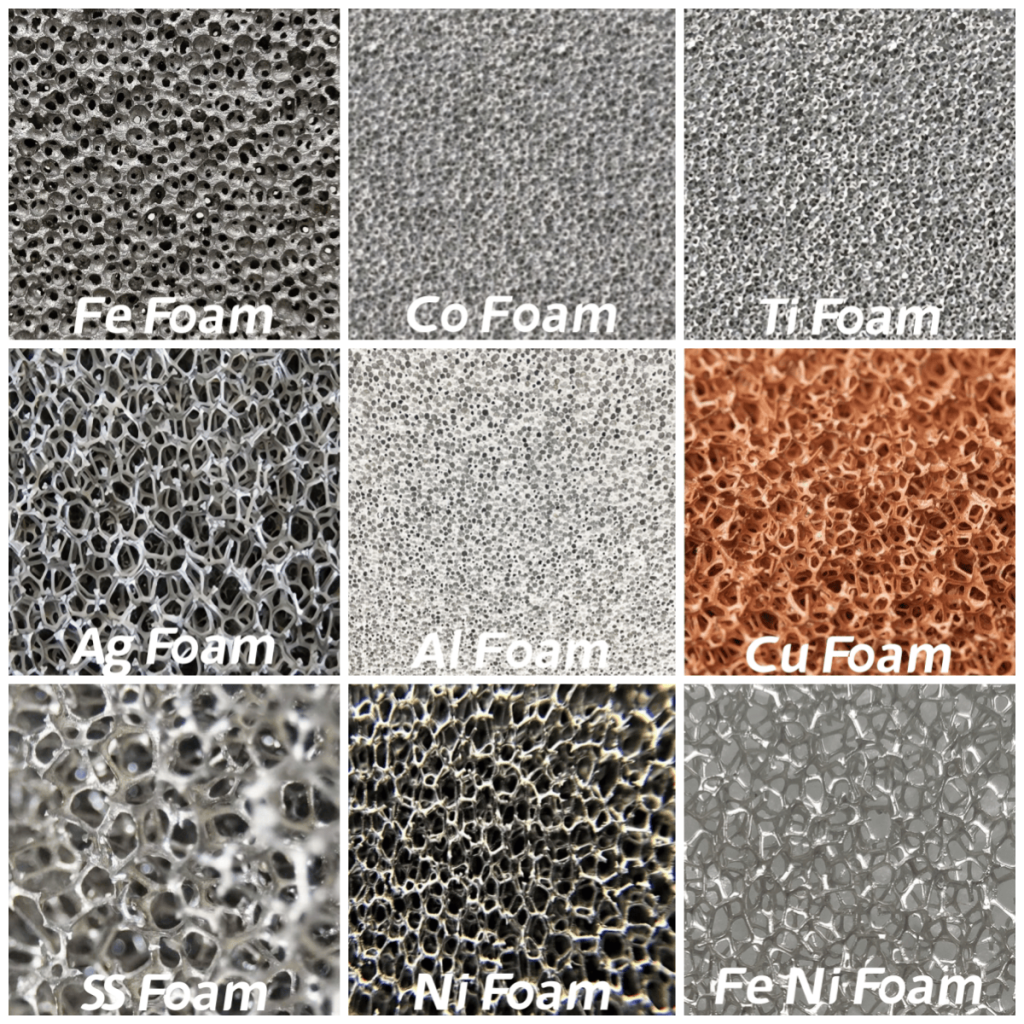

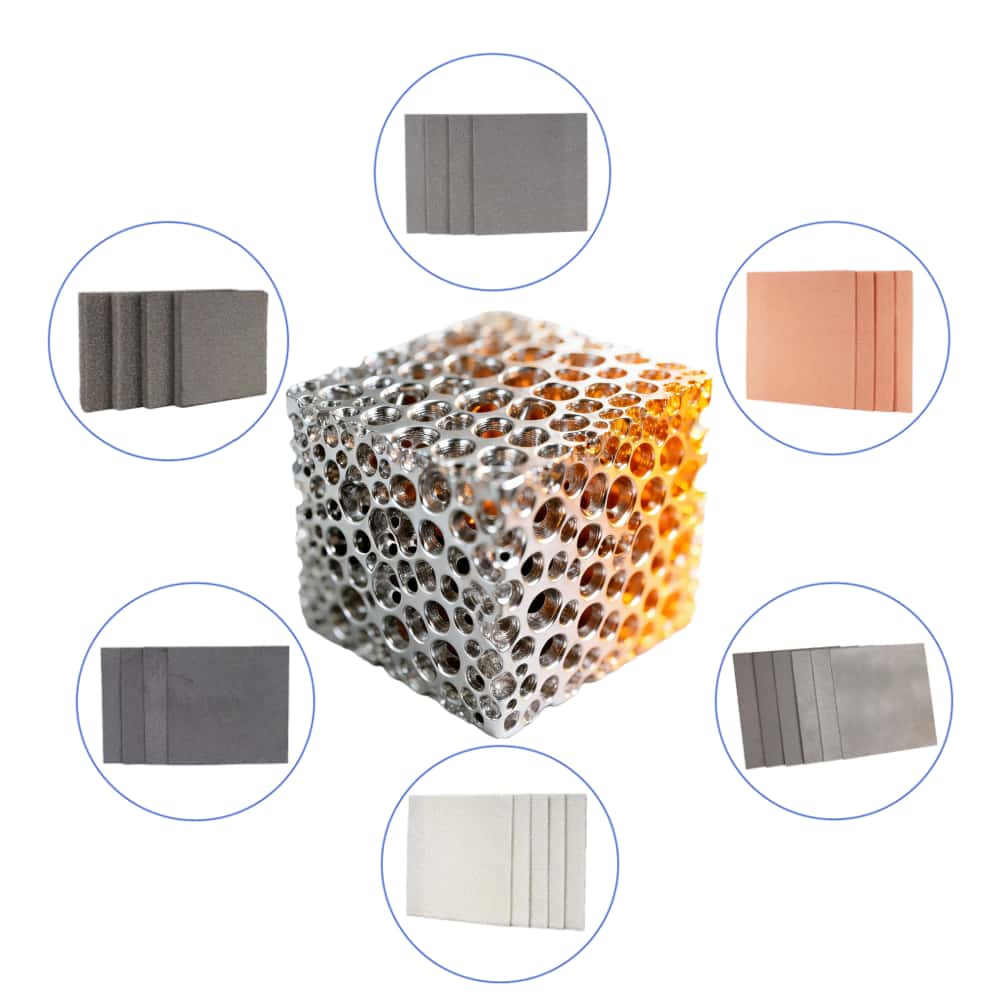

各種金属箔のカスタマイズについては、詳細はこちらの画像をクリックしてください:

|

|

|

|

|

|

|

タングステン箔 タングステン箔 |