High Conductive Carbon Coated Aluminum Foil Al Metal Foil for lithium ion Battery Substrate

Introduction

1.Improve the consistency of battery usage group and reduce battery cost significantly.

2.Improve the adhesion of active material and the collector, and reduce the electrode manufacturing cost.

3.Reduce the polarization, increase the rate and capacity, improve the battery performance.

4.Protection of fluid collection, extend battery life.

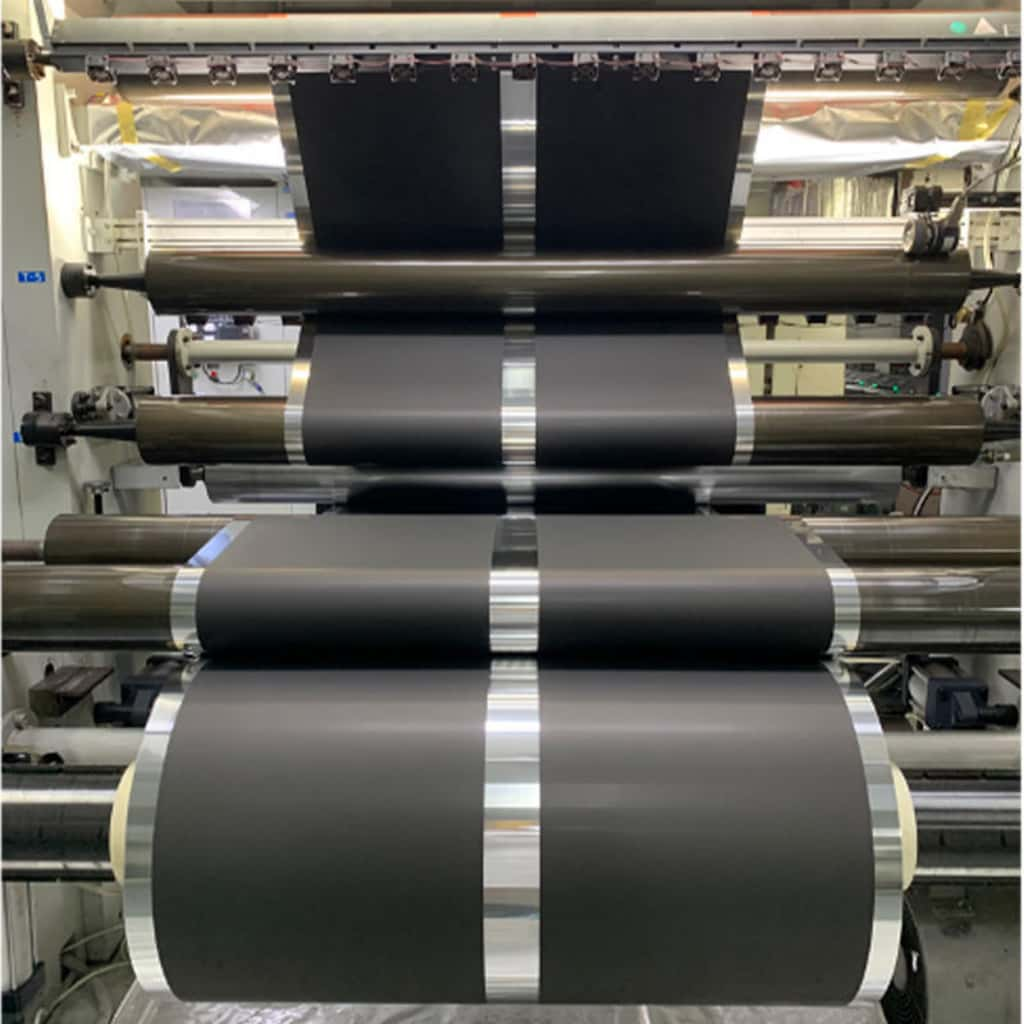

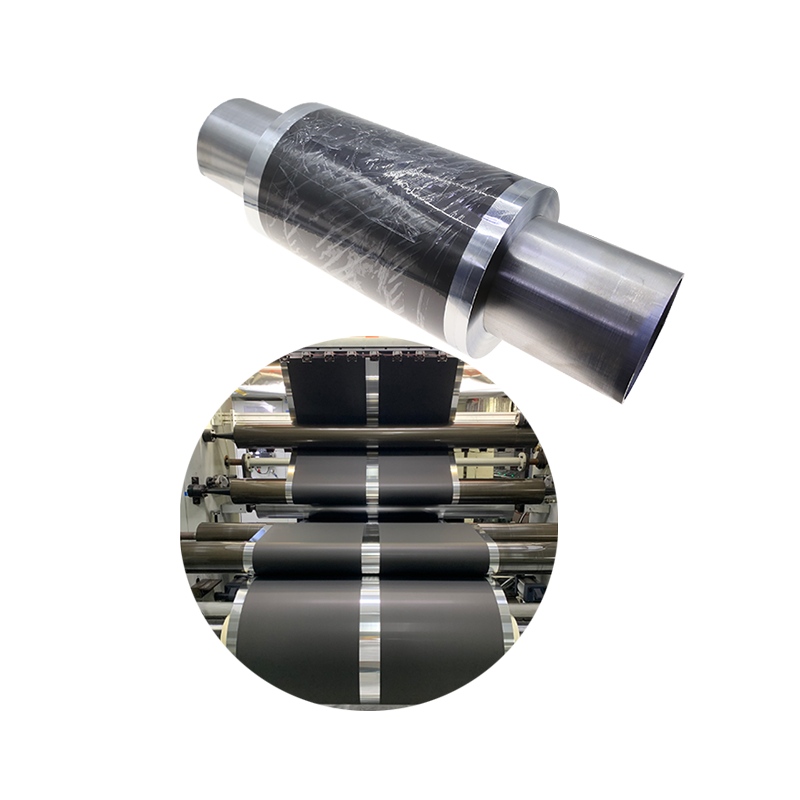

5.Possess Japan Fuji coating machine, slitting machine and automatic computer inspection rewinder machine.

6.Average coating speed reach 90-120m/min.

7.Product 21600m conductive coating aluminum foil every 8 hours,can be used for 200Kpcs 18650 core.

8.Roller coating width up to 1 meters.

9.Can adopt continuous or intermittent coating mode.

Specifications

|

Inspection item |

Parameters |

Unit |

|

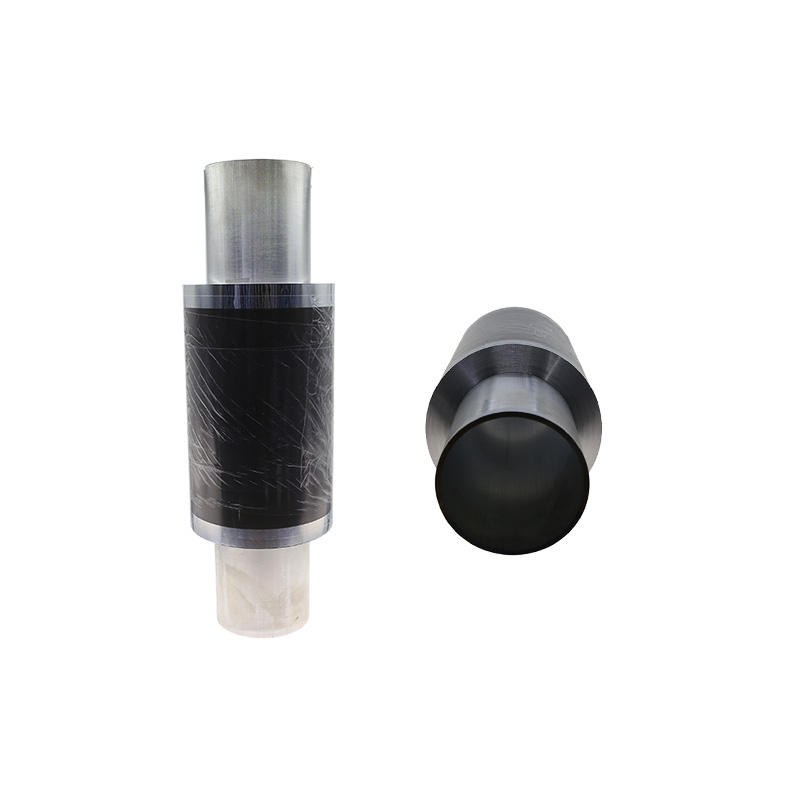

Original thickness (Al foil) |

15 |

um |

|

Double side coating thickness |

3 |

um |

|

Aluminum foil width |

309.6 |

mm |

|

Coating width |

280 |

mm |

|

Single side Average surface density |

0.42 |

g/m2 |

|

Tensile strength |

214.3 |

Mpa |

|

Extensibility |

1.583 |

|

|

Remarks |

If there are special requirements, can be customized |

|